While Equipment Parts Lists may not be as hidden as other gems I’ve discussed – this one is often delayed due to internal discussions of ownership and maintenance. Equipment Parts Lists, or EPLs as they’re called, are valuable time savers to technicians on the ground. However, the time and labor to set them up and the ongoing maintenance can put the use of this tool on the back burner for many organizations. Personally, I think this is short-sighted as the advantages far outweigh the internal “hot potato” game and the initial set-up time investment.

While Equipment Parts Lists may not be as hidden as other gems I’ve discussed – this one is often delayed due to internal discussions of ownership and maintenance. Equipment Parts Lists, or EPLs as they’re called, are valuable time savers to technicians on the ground. However, the time and labor to set them up and the ongoing maintenance can put the use of this tool on the back burner for many organizations. Personally, I think this is short-sighted as the advantages far outweigh the internal “hot potato” game and the initial set-up time investment.

An Equipment Parts List, as described in PeopleBooks is: A parts list corresponding to asset classes, groups, categories, types, and subtypes, or to any asset definition. The EPL can then be associated with a specific asset ID. EPLs can be comprised of parts in the Item Master, or Parts On-Hand (without an Item ID). They can be items that need to be purchased via Purchase Order, or parts in a formal Inventory.

The usual sticking points around using Equipment Parts Lists are:

- Who is going to set them up?

- Who is going to maintain the Item Master?

Both are valid concerns but a partnership between Operations and Purchasing groups will offer up the best combination. Operations is the group that knows what parts are needed for specific equipment. Purchasing is the group that updates and maintains the Item Master. Communication between the two teams will keep the information accurate.

There are significant time and cost savings to be garnered by having a short list of correct parts that may be required for repair or maintenance of equipment readily available for technician selection. These are created and maintained at the SET ID level so can be used across all business units in an organization.

Once an Equipment Parts List is attached to an asset it will be available to a technician creating a work order for that asset. The time saved in finding the right part in an inventory or purchasing catalog alone can be significant as can ensuring that the correct part will be ordered the first time.

Related: Here is the difference with Diversified Bronze & Manufacturing Inc.

An Equipment Parts List can be included in a task template as part of the preventive maintenance work order and is available for ad hoc corrective work orders. Once a technician selects the part from the list, adding it to the work order normal procedures for acquiring the part from Inventory or via a purchase order would be followed.

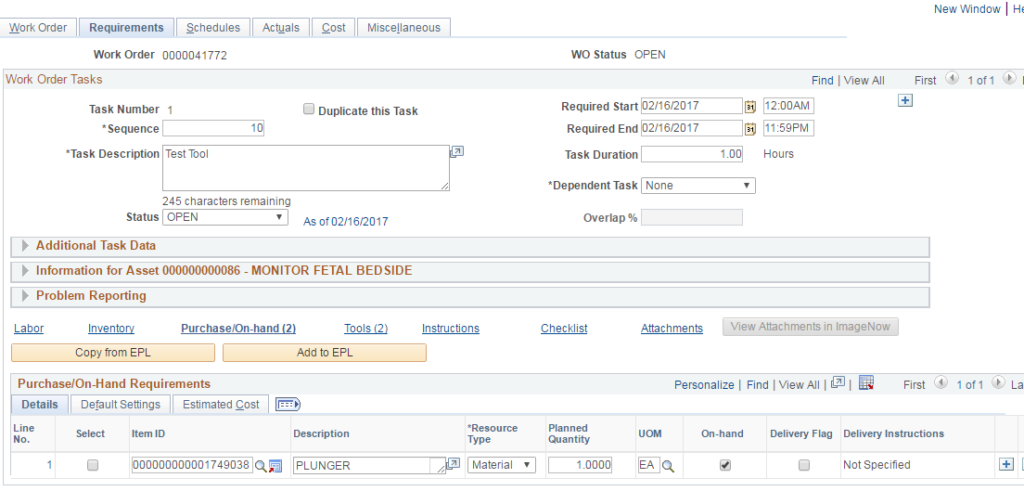

If an Equipment Parts List has been created and attached to an asset, when the work order is created the copy from EPL button will be active on the work order.

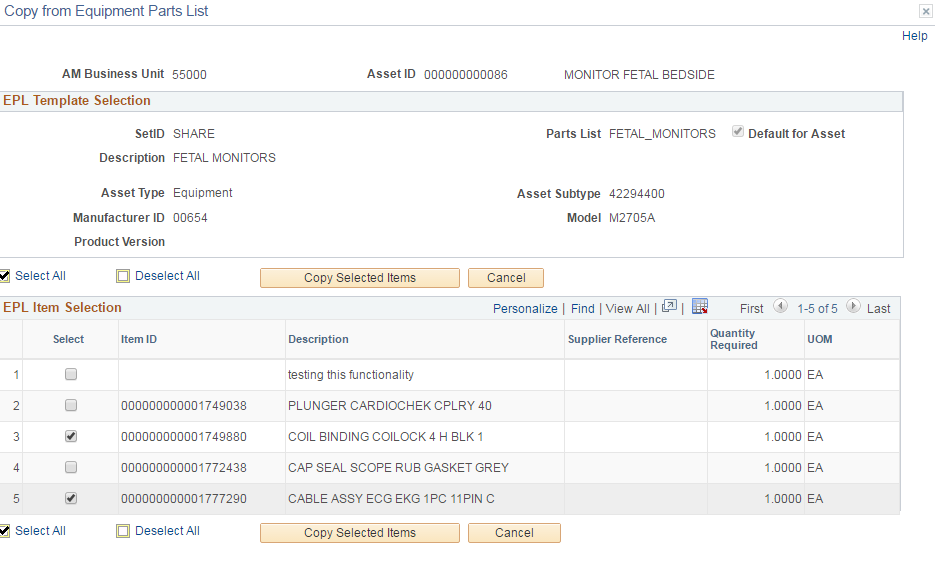

By clicking the button the technician will be able to select one or all of the parts from the list. It’s that simple!

Keep checking back as we dig deeper into the treasure chest, who knows what valuable gem you will find that can help you get more out of your investment.

If you have any questions or would like additional information about this or PeopleSoft Asset or Maintenance Management, please contact me at Robin.Cole@MIPROConsulting.com or Larry.Zagata@MIPROConsulting.com.